Those who have actually followed my shapes over the years may have noticed that the models that emerged from my rather selfish desire to shape the perfect boards for myself, have not been stagnant. They have evolved, along with my sensibilities, abilities, and knowledge of surfing and board design.

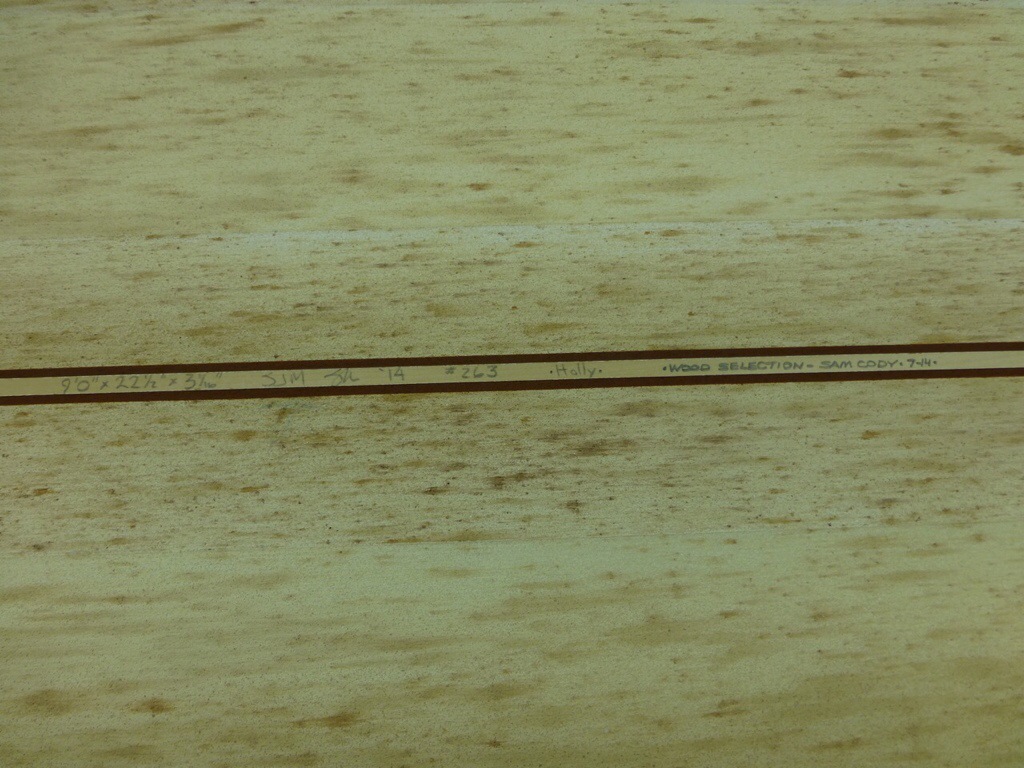

To be fair, no two hand shaped surfboards are ever identical. Even machine shapes vary depending on the final hand sanding and tuning. Even the unsung heroes at the factories (laminators, gloss and hot coat guys, sanders, fin guys, polishers) help determine the final result, each in their own way. Another factor for me though, it is my inability to shape as accurately as more experienced hand shapers. I am not one to rely on exact measurements of every aspect of the board. What consistency I achieve is sole a product of my doing each step of the shaping process the same each time. It’s an intuitive method that turns out shapes like mine because that’s just how I do it, each and every time. Often the process and what I see in front of me takes over, and in an effort to keep everything flowing and harmonious, goals and final results necessarily shift. I feel that far from being a bad thing, this reality allows for the opportunity to feel differences and learn from them, adding to the growing library of cause and effect in my mind.

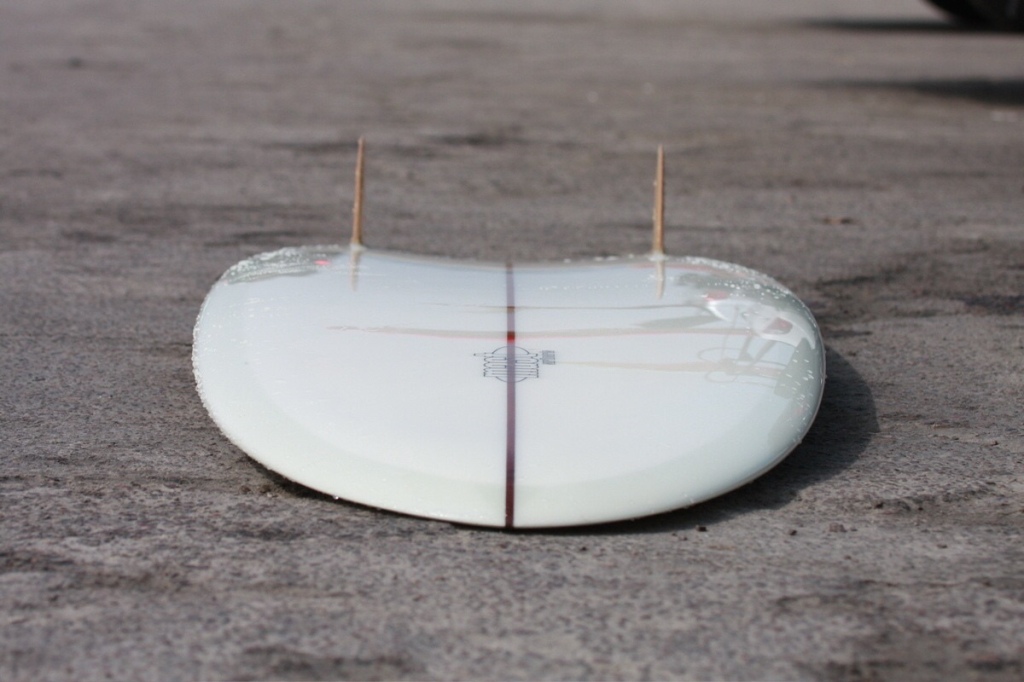

Here is an example of this process at work. I was able to pull a template off an extraordinary board that I had the good fortune to come across. For my first shape that I did for a friend from this template, I tried to match the original ‘70s shape, with as good of results as I could muster at the time. It worked very well indeed, and he still has it today, close to twenty years later. The second one, I made for myself, and I foiled out nose and tail a lot, carved deep bottom contours and really knifey rails. I surfed it to death. It was wide, but the fineness of the rails and foil made it extremely sensitive (which I like), while still planing nicely. I don’t want to say my surfing is tentative, but I am certainly no power surfer, so it suited me fairly well. The third one, again for a friend, I split the difference, and it ended up the best of the three, easy and fast. It had no element that stuck out as extreme (to me anyway), and it just worked nicely in a variety of conditions. Experiments like these are excellent learning opportunities, and I try to do them whenever I can afford to.

One of the great benefits of hand shaping, is the flexibility it allows. Adjustments can be made, board by board, to improve (hopefully) any design, and back up on things that may not work out as hoped.

All of this gets me back to the point of this article. My model designations must be looked upon as an indication of the general feel and utility that one can expect from any particular model. They may vary slightly from shape to shape, but they typically retain a particular feel and purpose.

So please keep in mind that if you have a board of mine from ten or twenty years ago and want to recreate it, I am happy to give it my best shot. I will be able to give you the same vibe, but it would be a very lucky day indeed that I could produce the exact same shape. If all of this sounds like me making excuses, that’s because I am. Whether it is a good excuse or not, I leave up to you.